This Startup’s Software Programs Industrial Robots, Not Coders

By Prachi Patel

THE INSTITUTE Robots are excellent at repetitive, tedious, and time-consuming jobs—which makes them beneficial in manufacturing. But training industrial robots requires substantial coding skills and knowledge.

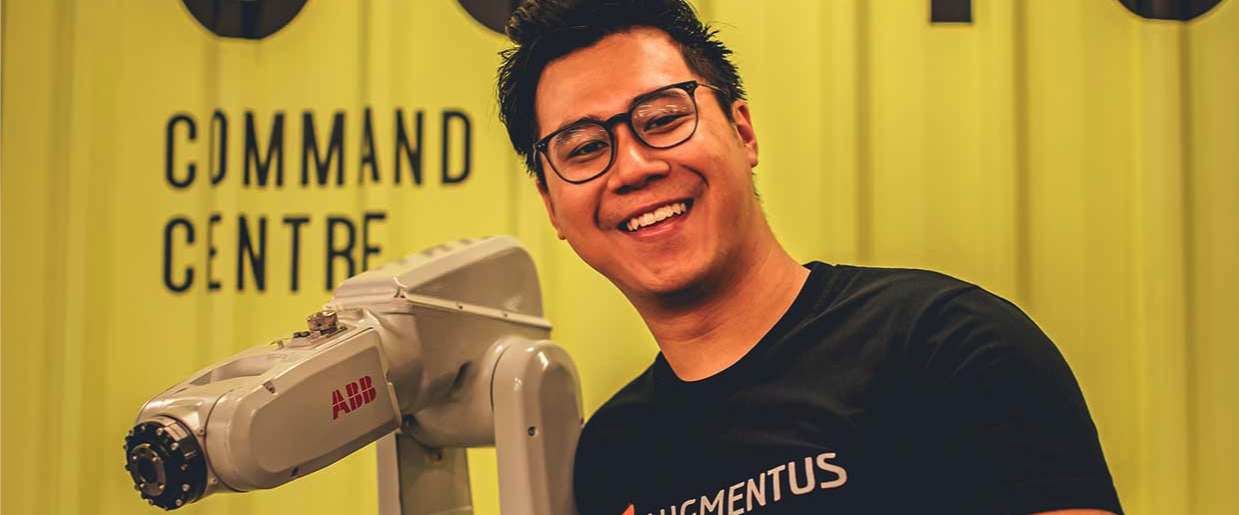

Singapore-based startup Augmentus, founded by IEEE Member Daryl Lim, Yong Shin Leong, and Chong Voon Foo, is trying to make automation more accessible with its intuitive robot-programming platform.

The platform’s software has a graphical interface that allows non-technical users to program industrial robots in minutes, says Lim, the startup’s chief operating officer. It also has an integrated artificial intelligence model that lets clients train the software to identify objects such as car parts. The model uses computer-vision algorithms, like the ones used for object and facial recognition in digital images.

Augmentus in December was named one of four IEEE Entrepreneurship Stars at Slingshot 2020, one of the biggest startup competition events in the Asia Pacific region. The award recognizes budding ventures driven by engineering innovations that align with IEEE’s core mission. Awardees become honorary IEEE members for a year, and they receive mentorship and support from the IEEE network.

An industrial robot being programmed with Augmentus’s software, which has a graphical interface that allows non-technical users to program industrial robots.

Most Augmentus clients are advanced industrial manufacturing companies that produce automotive or machinery parts. The companies use robots for quality inspections, spray-coating or polishing parts, or loading and unloading inventory.

By making industrial robots easier to program, Lim says, the software can help businesses increase efficiency and reduce costs—which would in turn help retain local manufacturing jobs.

“We want to lower the time, skill, and cost barriers for companies to adopt robotic automation,” Lim says.

INCREASING EFFICIENCY

Industrial robots can be costly beasts to tame. Teaching a robotic arm to do a seemingly simple task, like sorting objects or moving them from a bin to a conveyor belt, typically requires thousands of lines of code, Lim says. The arduous coding process has to be repeated every time the arm must be reprogrammed for a different task.

To add to the problem, robots made by different manufacturers often use different programming languages. And programmers with the requisite coding skills are in short supply.

It all translates to higher expenses.

“Close to 70 percent of the cost of an industrial robot is software- and programming-related,” Lim says.

Augmentus software does not require the user to create any code. Instead, factory technicians can program robots or robotic parts with an iPad and an Apple Pencil stylus.

The technician selects its robot and equipment from the software’s menu, uses the iPad’s camera to scan the area in which the robot works, and then—with the stylus—plots points on the screen to map out the path the robotic arm will take for its task. The software, which runs in the cloud, then automatically generates code to create the optimal path for the bot. Users can test and verify the code via virtual simulations before deploying it on a factory floor. They can edit it if need be.

Compared with the traditional coding route, the startup’s technology allows companies to develop and deploy robots 10 times faster and for a 10th of the cost, Lim says.

The software is mostly being used now by manufacturing companies for spraying and inspecting parts, but the team is updating it for new applications such as welding and sanding.

OVERCOMING BARRIERS

Lim met Leong and Foo at an industrial networking event in 2019. They got to talking about their first-hand experiences with the barriers that high technical requirements and skillsets had created in the adoption of technology, especially robot programming.

“This is particularly the case for industrial automation, where users can spend countless hours doing simple robot movement and integration work,” Lim says. “This inspired us to build an intuitive, graphical robotics platform that simplifies and unifies the development and operation of industrial robots.”

When the three engineers met, Lim was chief executive of Edge Neo, a company in Singapore he launched in 2015 after earning a bachelor’s degree in banking and finance from Singapore Polytechnic. The company provides encryption algorithms for blockchain technology to clients across Southeast Asia.

Leong and Foo were both working at Singapore’s Agency for Science, Technology, and Research, developing robotic solutions for multinational companies, and had spent countless hours programming and integrating robots.

Leong and Foo were both working at Singapore’s Agency for Science, Technology, and Research, developing robotic solutions for multinational companies, and had spent countless hours programming and integrating robots.

The trio launched Augmentus in December 2019. Now, a little more than a year later, the venture-capital-funded seed-stage startup has 15 employees.

NEW OPPORTUNITIES

Launching at the start of the COVID-19 pandemic presented some challenges, Lim says. It became difficult to give prospective clients physical demonstrations and hands-on experience with the company’s product. Instead, the startup conducted virtual demonstrations that involved product videos and Zoom information sessions.

But the pandemic also has brought the startup, several clients, from different industries. A handful of large medical companies are interested in automating processes such as pipetting, which involves moving small, precise volumes of liquid using narrow tubes. And with international trade and travel becoming more difficult, there has been a growing demand from large agricultural companies, as well as small urban farmers, who want to automate processes such as crop harvesting and packaging.

“The concern with agriculture in developed countries is always manpower and labor shortages,” Lim says.

Go to IEEE The Institute to read the complete article.