4 Products That Make Sense to Manufacture in Orbit

By Prachi Patel

Space is open for business, and some entrepreneurs plan to make the final frontier into a manufacturing hub. There’s plenty of real estate. But it takes a few thousand dollars to launch a kilogram of stuff into space.

“The key question is: What is it that justifies the expense of doing these things in low Earth orbit?” says William Wagner, director of the University of Pittsburgh’s McGowan Institute for Regenerative Medicine, which will conduct biomedical research on the International Space Station (ISS).

Here are some technologies that might merit the “made in space” label.

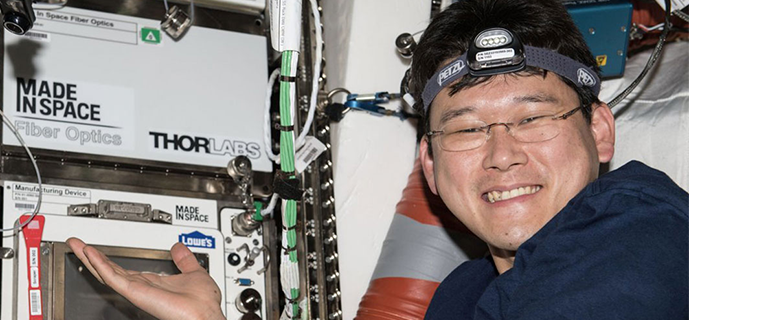

Fiber-optic Cable

Made from fluoride glass, a kind of fiber-optic cable called ZBLAN could have as little as one-tenth the signal loss of silica-based optical fibers.

But quality ZBLAN fibers are hard to make on Earth. As the molten glass is stretched into fibers as thin as fishing line and then cooled, tiny crystals sometimes form, which can weaken signals. Microgravity suppresses the formation of these crystals, so fibers made in space would carry more data over longer distances.

More data plus the need for fewer repeaters under the ocean would justify a higher price, says Austin Jordan of Made in Space, which plans to produce such fibers in space for terrestrial clients. “The math works. It would pay for itself and drive a profit,” he says.

Two other companies, Fiber Optic Manufacturing in Space and Physical Optics Corp., also plan to make ZBLAN fibers in low Earth orbit.

Organs

There are 120,000 people waiting for an organ transplant in the United States alone. “Most will never see one, there is such a shortage,” says Eugene Boland, chief scientist at Techshot, which wants to print human hearts in space.

The heart, with its four empty chambers and highly organized muscle tissue made of different types of cells, is virtually impossible to print on the ground. On Earth, tissues printed with runny bioinks made of gel and human stem cells collapse under their own weight. Scientists must add toxic chemicals or a scaffold.

Printing hearts and other organs in microgravity could be done using pure bioinks. “The cylindrical shape extruded from the nozzle is maintained, so you can build a more fragile 3D structure that would allow cells in the gels to secrete their own matrix and strengthen up,” says Wagner. And the printed layers fuse together without forming the striations seen in constructs printed on the ground, Boland says.

Techshot, which is based in Greenville, Ind., is partnering with 3D-bioprinter manufacturer nScrypt. Their first bioprinter went to the ISS in July, but the small patch of heart muscle it printed didn’t survive reentry. The next mission, which launched in November, should result in thicker tissue that can be tested on Earth when it returns in January.

Go to IEEE The Institute to read the complete article.